Secure logistics – internal and external

Logistics from incoming goods to the customer

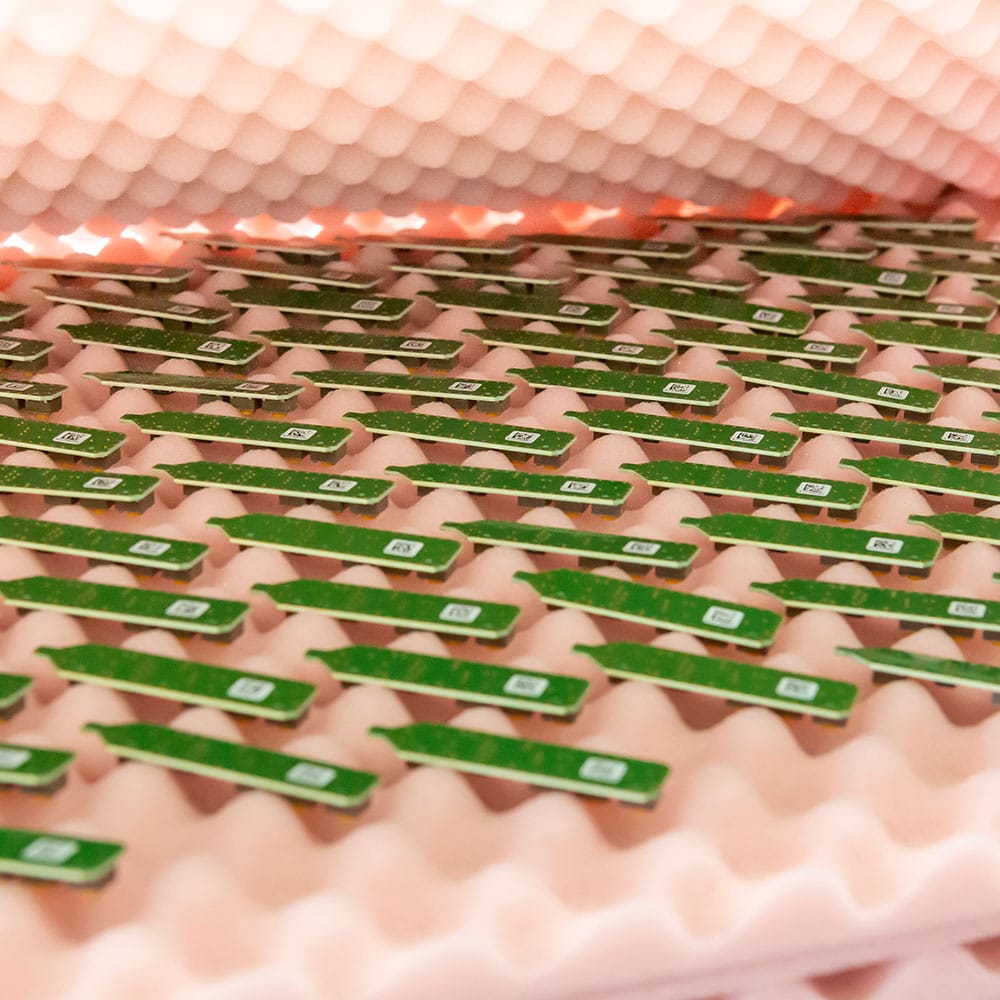

Our trained specialists ensure an efficient and smooth process from receipt in the incoming goods department, to storage and distribution to the workstations and assembly machines.

Short paths

Fast material supply

With the help of the system, the materials requested from production are delivered in the milk run to the Kanban stations and directly to the individual workstations. The fitted assemblies then follow a predetermined route within production to the test field and dispatch. The transfer from internal to external logistics is performed via a shipping company or our in-house delivery service.

Our mission statement

Our industry-specific solutions

Long-term customers from core industries rely on our industry expertise and see ACD Systemtechnik as a reliable partner for the production of their assemblies and systems in compliance with applicable regulations and standards.

CIPs in the EMS logistics area

Essential component in the EMS area

The improvement projects (CIPs) are part of the company’s lean principle and mesh between production and logistics several times and are tailored to the individual requirements.

That’s why the CIPs do not run separately as an isolated solution, but also consider upstream and downstream process participants in accordance with lean principles in the EMS value stream. This guarantees an efficient and route-optimised material supply, especially in the logistics area.