Technology – SMT (soldering)

Soldering process for SMD components

The soldering processes after SMT assembly are the predominantly used reflow soldering process, the vapour phase process and hand soldering. ACD Systemtechnik can solder all SMD-equipped components using state-of-the-art technical equipment.

SMT – soldering

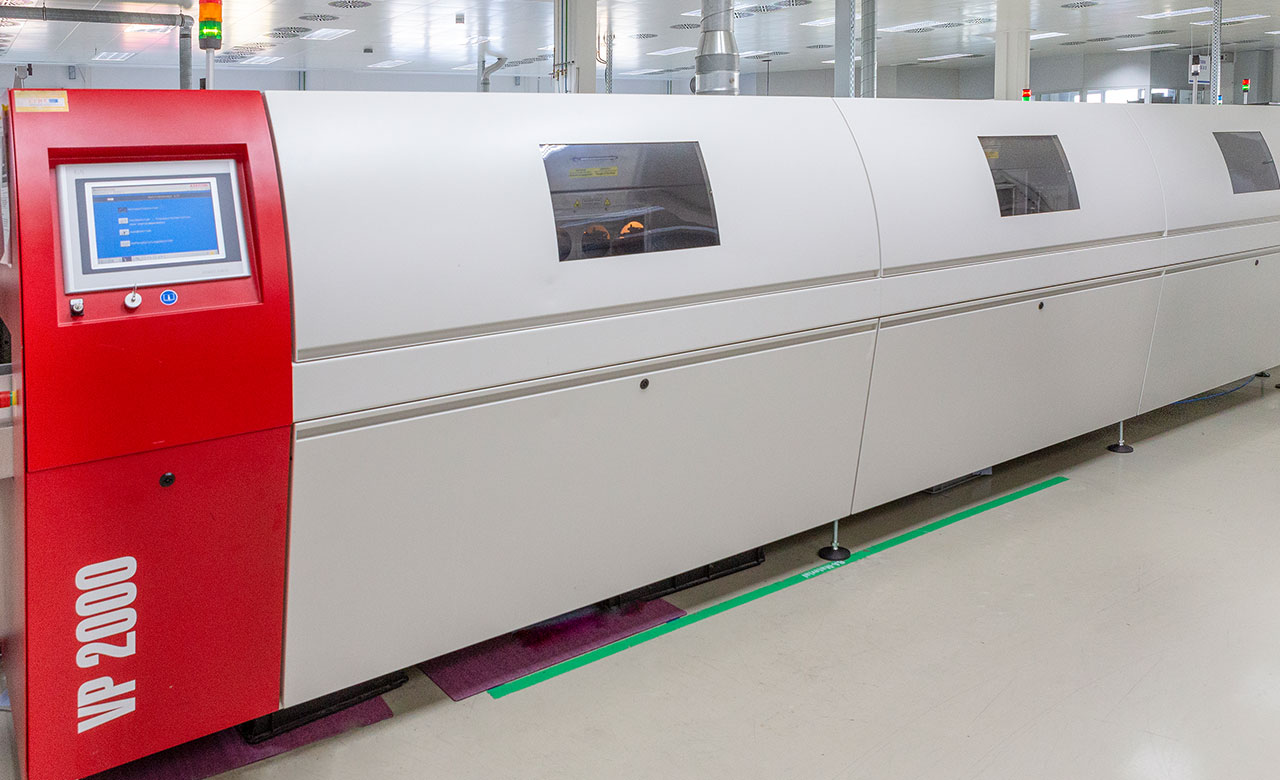

Reflow soldering process

The term reflow soldering refers to a soft soldering process common in electrical engineering for soldering SMD components as the next process step following the SMD machine assembly.

Reflow soldering is the standard method for soldering SMD components. Components, solder and flux are already on the pads, so that in the reflow soldering process only thermal needs has to be fed to the assembly in a precisely defined temperature-time profile. This causes the entire assembly to heat up to above the melting temperature of the solder paste, which melts and forms the soldered joints.

SMT – soldering

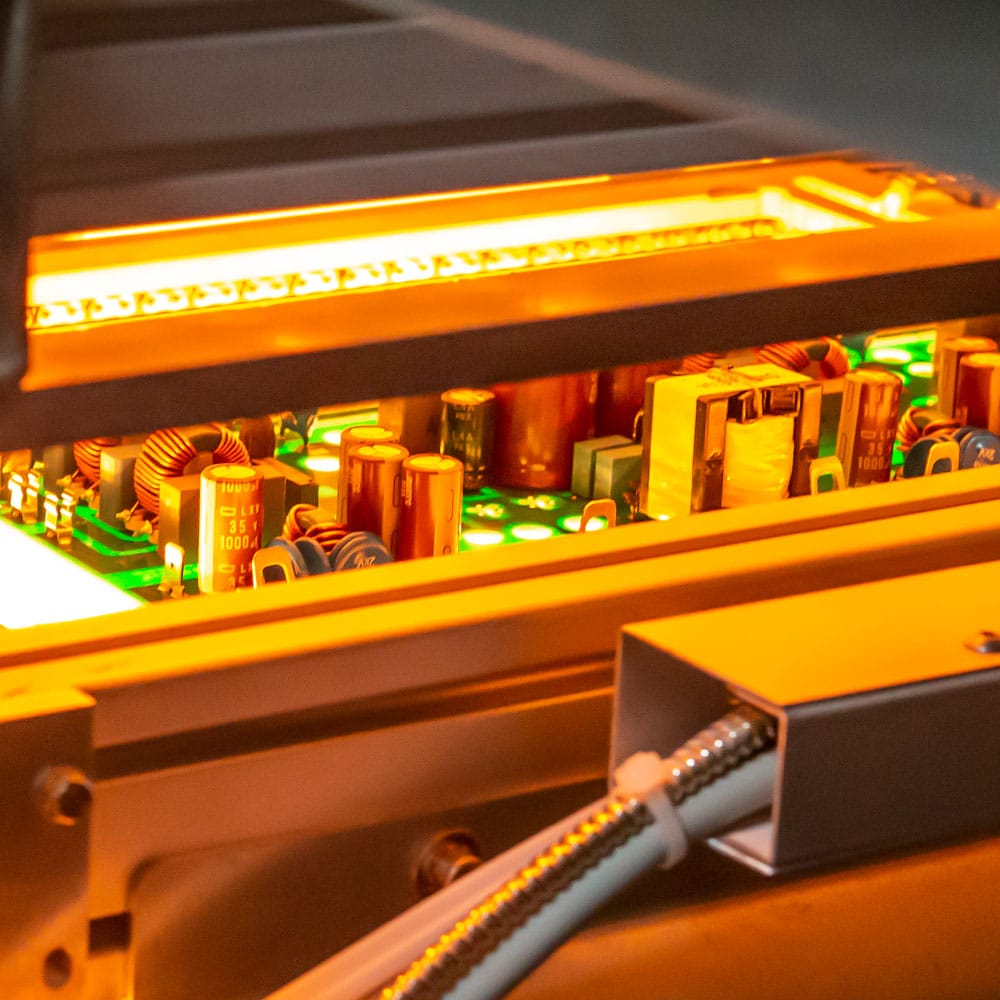

Vapour phase soldering

Heat can be transferred through the condensation of vapour. This principle is used in vapour phase soldering to solder electronic components using the reflow method.

However, water vapour cannot be used in this process. Special demands are placed on the vapour medium. It must not lead to corrosion, be electrically non-conductive and allow high steam temperatures without high pressure.

SMT – soldering

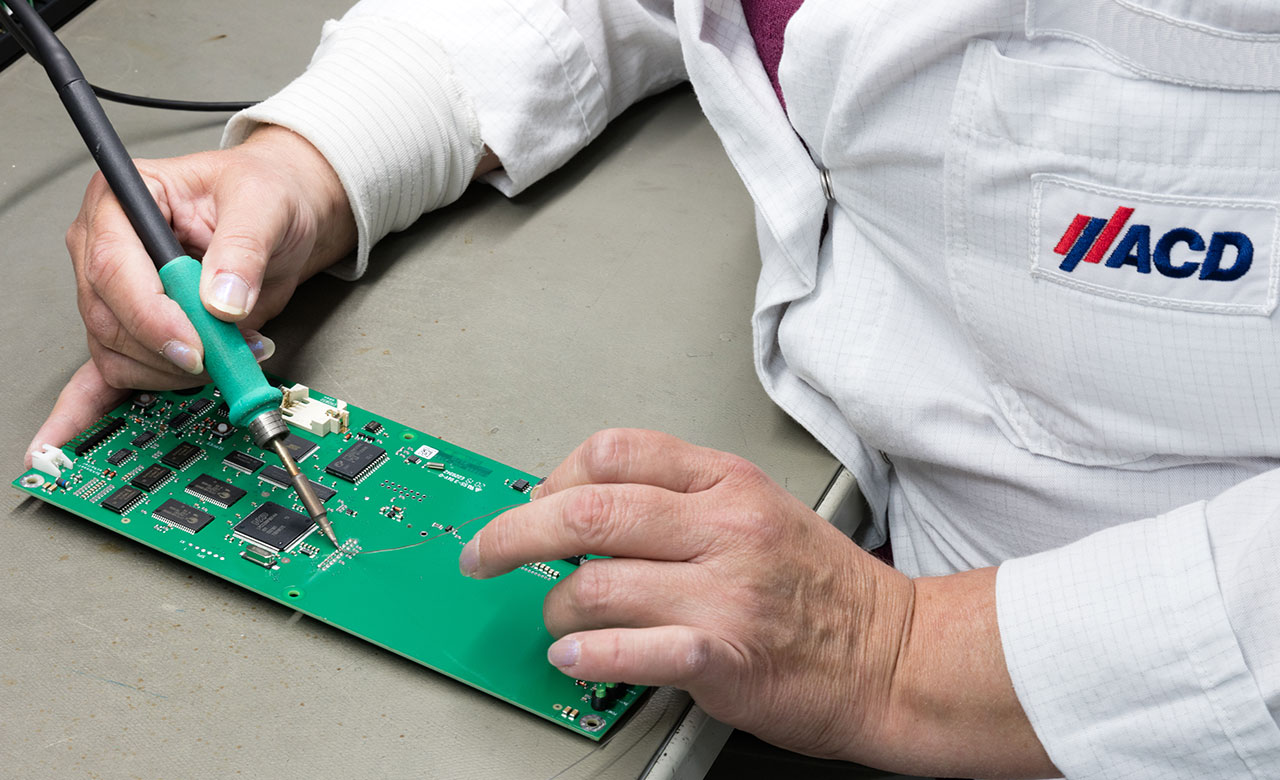

Hand soldering

For very small quantities or SMD components (design, placement on the circuit board) that cannot be fitted by the machines, our specialised team professionally solder the SMD components by hand with appropriate visual aids to enlarge them.

SMT assembly soldering technology

Reflow soldering SMD components

The solder paste applied by screen printing in the upstream process, to which the components adhere during SMD assembly, is melted by the multi-stage heating process in the reflow oven until the solder has reached its melting temperature. This results in the electrical connection between the connection pins of the components and the circuit points.

SMD component vapour phase soldering

Condensation soldering

Fluorocarbons with selectable boiling points between 180 – 260°C are used as media. In contrast to normal convection (carrier medium gas), heat can be transferred faster to the assembly to be soldered by up to a factor of 10. The process is also called condensation soldering.

SMD component hand soldering

Manual soldering process

Skilfully and for many years, our specially trained specialists solder the miniature SMD components on the one hand and SMD components that are placed on the circuit board in places that cannot be assembled by machine with sure instinct.