Quality – Optical test procedures

2D / 3D optical and X-ray inspection

To ensure 100% quality of the assembly, ACD Systemtechnik provides various optical test methods in the SMD and THT assembly process.

Visual testing after SMD assembly

Automatic optical inspection – SMT (AOI)

Automatic optical inspection (AOI) checks the arrangement of the SMD assembly: scanning the assembly with AOI systems and comparing the results with the CAD data (Computer Aided Design) of the circuit board. Image processing methods are used to find incorrectly assembled, twisted or misaligned components and contamination

Visual inspection after the SMD assembly of complex components

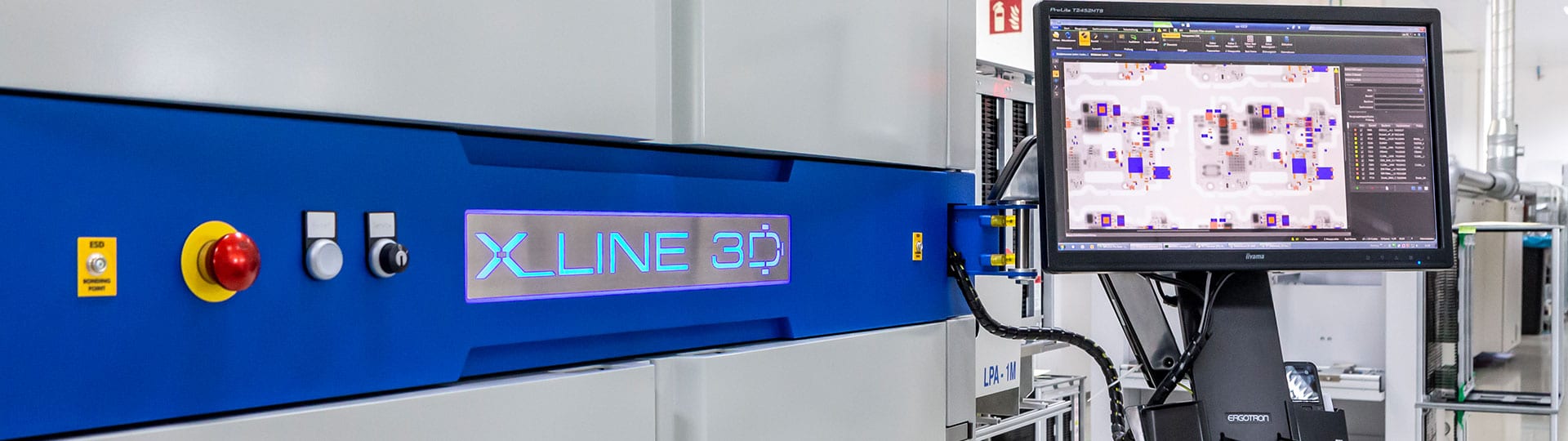

Automatic X-ray inspection – SMT (AXI)

Automatic X-ray inspection (AXI) checks components that cannot be checked by the optical SMT AOI. The 2D / 3D X-ray inspection is used to check the correctness of the soldering points. This applies, for example, to BGA components with multi-pole connections below the integrated circuit housing.

Visual testing after THT assembly

Automatic Optical Inspection – THT (AOI)

Automatic optical inspection (AOI) checks the arrangement of the THT assembly. Image processing methods are used to find incorrectly assembled, twisted or misaligned components and contamination.

Visual inspection according to the assembly plan

Visual inspection

If visual inspection is required, a manual visual inspection is carried out based on the assembly plan. The test is IPC-A-610 compliant. Here magnification aids are used for very small components and UV light is used for paints

Optical test methods with a clear view

Starting with optical processes

We use different optical methods in the process to ensure the quality of the assembly. Our long-standing and experienced staff in the EMS quality assurance field carry out these tests carefully and cost-consciously.

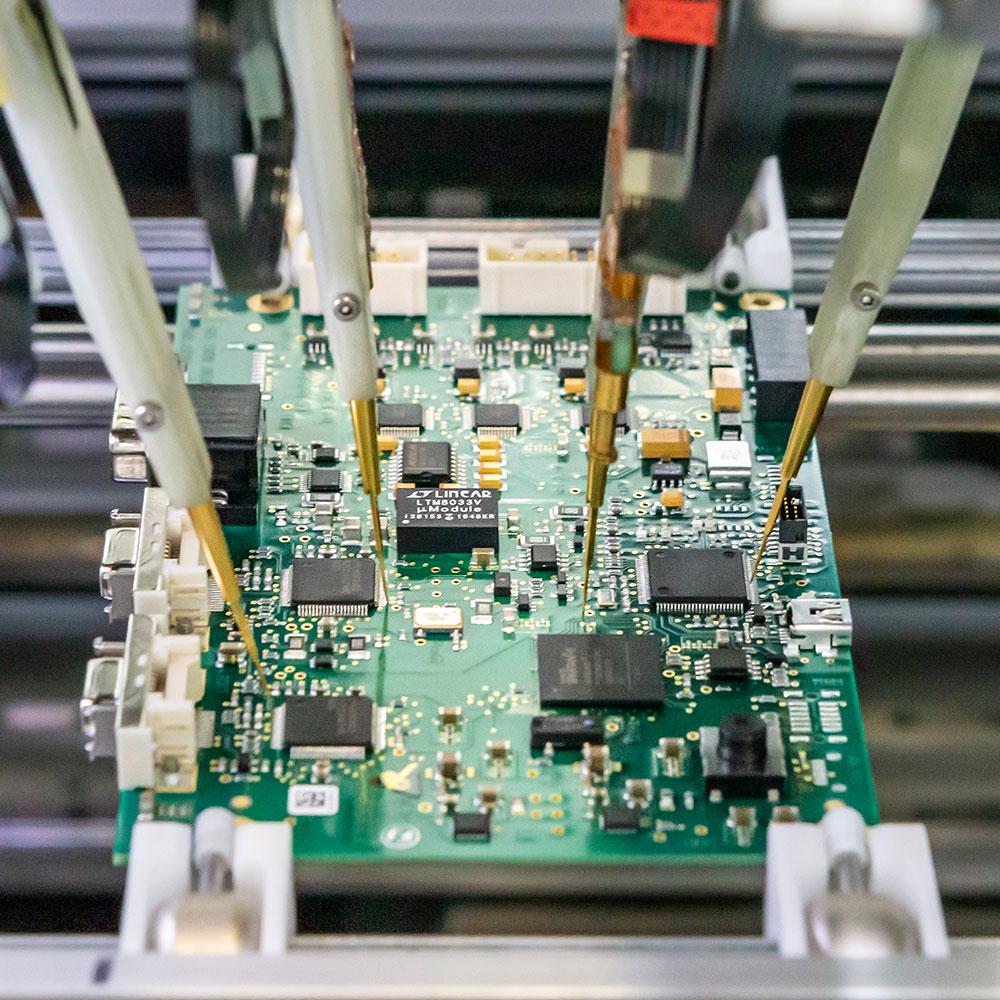

Testing during SMT assembly

Inline SMD process control

During the assembly process through the SMD assembly lines, both the lifting of the components and the assembly are monitored in-line by camera systems. This is the first optical inspection in the process.

Testing after SMD assembly (SMT-AOI)

Correctly assembled SMDs?

After completing the soldering process in the SMD assembly in the reflow oven or vapour phase oven, all SMD assemblies are 100% visually inspected. Attention is paid to the correct assembly of the components with the correct polarity and in the correct position with the aid of magnifying optics.

X-ray testing for BGAs (SMT-AXI)

Checking hidden solder joints

Multi-pole SMT components have spherical connection points (BGA = Ball Grid Array) below the component housing. Our 2D and 3D X-ray inspection stations are used to check the quality of the soldered joints on these multi-pole ICs (integrated circuits).

Manual visual inspection

Identifying assembly quality

We use visual inspection according to the IPC-A-610 standard to manually check the quality. Our experts are excellently trained in evaluating the quality of electronic assemblies.