Mobile Workstation MAX BE BWS-R

MAX BE BWS-R

The MAX BE BWS-R Mobile Workstation features a roller battery changing system for easy battery changing without lifting.

Product Information

Mobile Workstation MAX BE BWS-R: Easy Battery Change with the Powerstation

- Flexible modular system with countless options

- Variable ergonomic height

- Three power classes: 375 VA, 800 VA or 1,200 VA

- With 24 V or 230 V working voltage

- Proven battery management system

- Easily change batteries without lifting with the ACD Powerstation

- Country-specific versions with all EU approvals

- FI circuit breaker

- Suitable for shift operation

- Smooth running hard floor casters (industrial grade)

A short video about the use of our mobile workplace at Goldhofer AG in Memmingen shows very clearly how travel time can be saved and IT equipment made mobile.

Technical Data

The data of the MAX BE BWS-R

Basic structure

- Aluminum base frame with four swivel castors (two with parking brake)

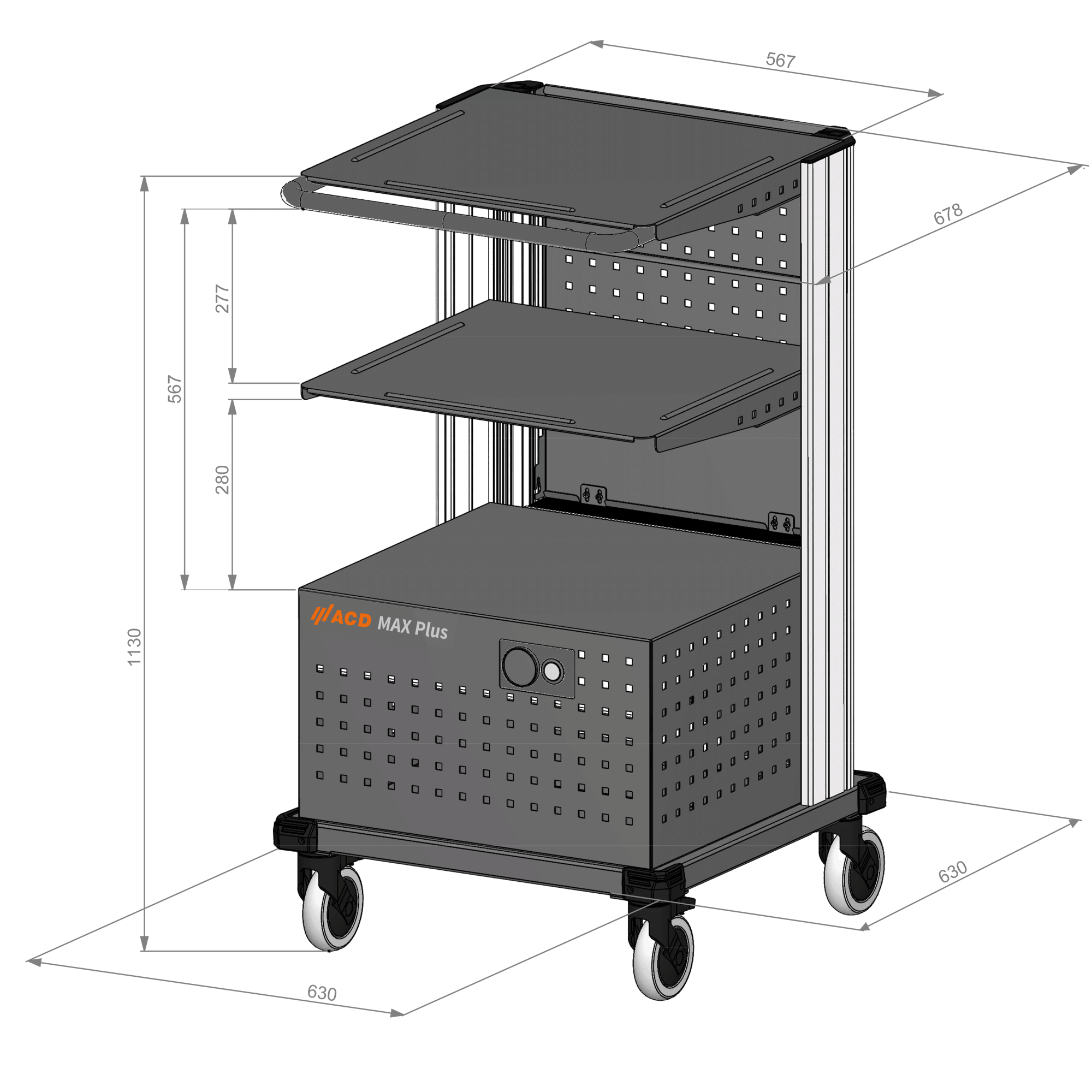

- Working height variably adjustable; standard 1,130 mm

- Easy to move due to ergonomic handle and large rollers

- Very stable due to external castors and low center of gravity

- Dimensions: 575 x 1,130 x 575 mm (W x H x D)

- Weight approx. 110 kg (depending on version)

- Temperature range 0 °C to + 40 °C

Equipment options

- MAX BE BWS-R 300:

On-board sinus power inverter 230 V AC/375 VA - MAX BE BWS-R 750:

On-board sinus power converter 230 V AC/800 VA - MAX BE BWS-R 1200:

On-board sinus power converter 230 V AC/1200 VA – Laser printer-capable - MAX BE BWS-R OWR:

Without inverter

Equipment MAX BE BWS-R

- Support: 500 x 445 mm (W x D); support height adjustable

- Rear panel standard with document pocket

- Rolling battery replacement system for MAX powerstation; the video shows easy battery replacement

- OnBoard Charger 12 A

- 2x fleece batteries 12 V/60 Ah (maintenance-free)

- 24 V DC connection incl. plug

- Battery controller to display the battery capacity incl. acoustic and visual warning when reaching the discharge voltage with automatic shutdown

- 5-/6-way Schuko power strip (country-specific) with residual current device (RCD) (not with MAX BE BWS-R OWR)

Case Study

Our services with Goldhofer

With the current solution, significantly fewer ground conveyors are required, routes are saved and throughput has been significantly increased. The individual load carriers in the goods receiving area now have to be moved significantly less. In addition, the employees significantly reduced their distances through the MAX.