Quality – climate test

Warmed up and cooled down

To ensure 100% functionality in continuous operation, ACD Systemtechnik provides various climate test methods: Run-in and burn-in.

Climate test

Run-In

The failure safety of assemblies is tested in the run-in procedure by subjecting them to a cyclical temperature change with the supply voltage connected and with a base load.

The temperature range to be tested normally lies within the temperature range of the later application of your assembly. An in-depth test of the solder joint and component quality is carried out using an endurance test program.

Climate test

Burn-In

In the burn-in test, the components to be tested are tested under high loads as simulated ageing of the assemblies with temperature / humidity profiles over longer periods of time in order to identify any problems that may arise at an early stage.

The point is to identify the components that would fail first in regular use. As a rule, the components are stressed sufficiently so that fault-prone components fail that were not noticeable in the previous function tests and during the X-ray inspection.

Temperature tests in continuous operation

Temperature and humidity

Simulation use in all climatic regions. With the use of our climatic cabinets, we simulate rough environmental conditions to ensure the continuous operation of the assembled circuit boards. Temperature profiles are run through especially according to the specifications of the test regulations of our customers and successfully completed with the corresponding test protocols.

Electrical load situation

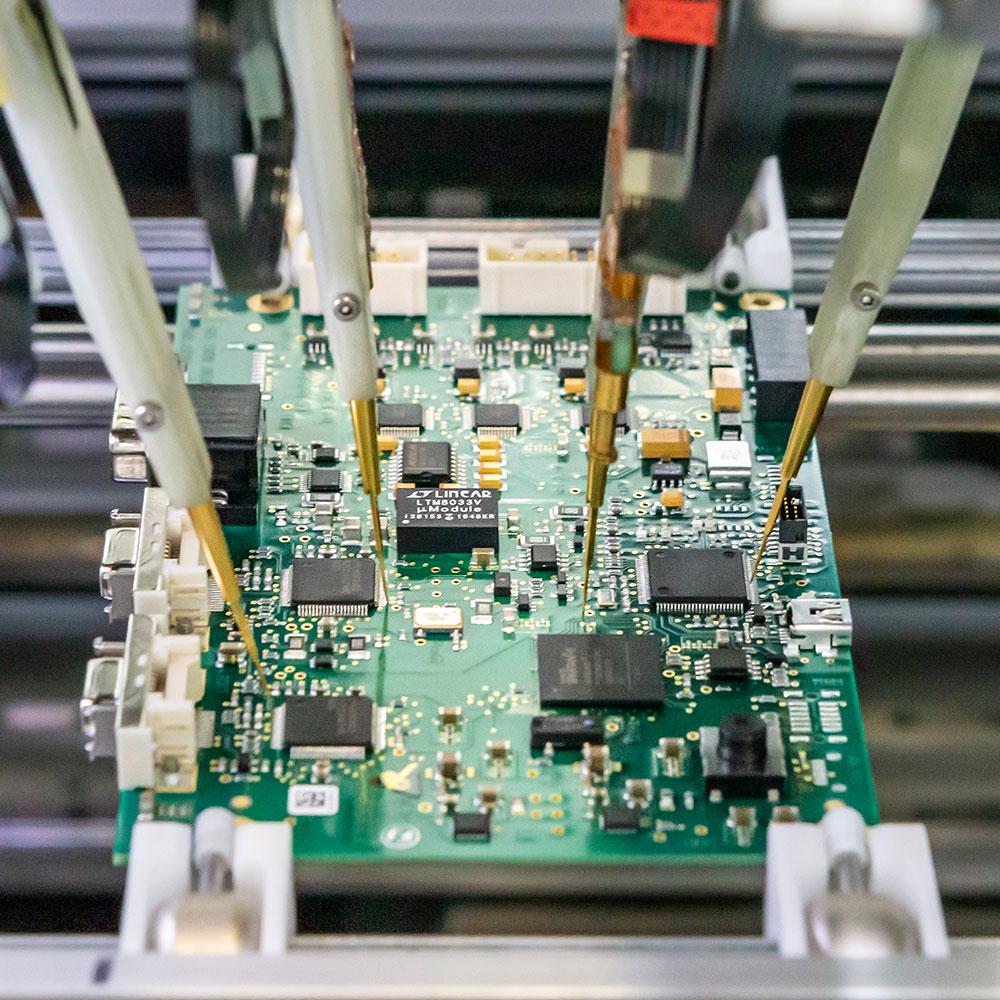

Burn-in stress test

Here, our EMS test field employees carry out long-term electrical tests in particular in order to detect possible failures of the electronics due to this stressful situation for the assembled SMD or THT modules, and thereby to guarantee that 100 percent functional electronic modules are delivered to our customers.