Technology – THT (soldering)

Soldering process for wired components

The soldering processes in the THT soldering process is different from SMT soldering. On the one hand, the wave soldering process is used and the second automatic process is selective soldering. The hand soldering process can also be used.

THT – soldering

Wave soldering

Wave soldering is a system used for bulk soldering of electronic assemblies. Divided into 4 phases, a soldering frame runs through the system fully automatically. Starting with the flux application through the spray fluxer, where the entire surface of the circuit board is wetted with flux. The other sections are different preheating areas for homogeneous and therefore stress-free soldering of the components.

Once heated, the circuit board is then soldered. During the soldering process, the frame is transported over a solder wave and is wetted by the wave over its entire width in a strip of approx. 30 cm. The soldering point is formed on the pads exposed by the solder mask. Finally, the frame goes through a cooling tunnel back to the workplace where it can be removed from the conveyor belt. The wave soldering system should always be preferred when soldering a large number of pieces in the best possible quality over the least amount of time.

THT – soldering

Selective soldering

This is an in-line selective soldering machine with a flux module for the selective application of the flux and several preheating and soldering modules. The solder level, the solder wave height and the solder temperature are continuously monitored. The electromagnetic solder pump without moving parts ensures a constant flow rate of the solder and the wave height can be precisely adjusted.

With the spray fluxer, points or lines can be applied in a targeted manner, which leads to a very clean and economical process. The components to be soldered can also be specifically controlled and soldered with the help of various nozzle sizes. The preheating consists of short-wave IR emitters on the underside. In addition, a convection top heater ensures that the circuit board is warmed through homogeneously in order to enable the components to be soldered with as little stress as possible. The use of the selective soldering system should always be considered if a circuit board is assembled with SMDs on both sides for design reasons.

THT – soldering

Hand soldering

Tiny quantities or very heavy and large components are soldered by hand.

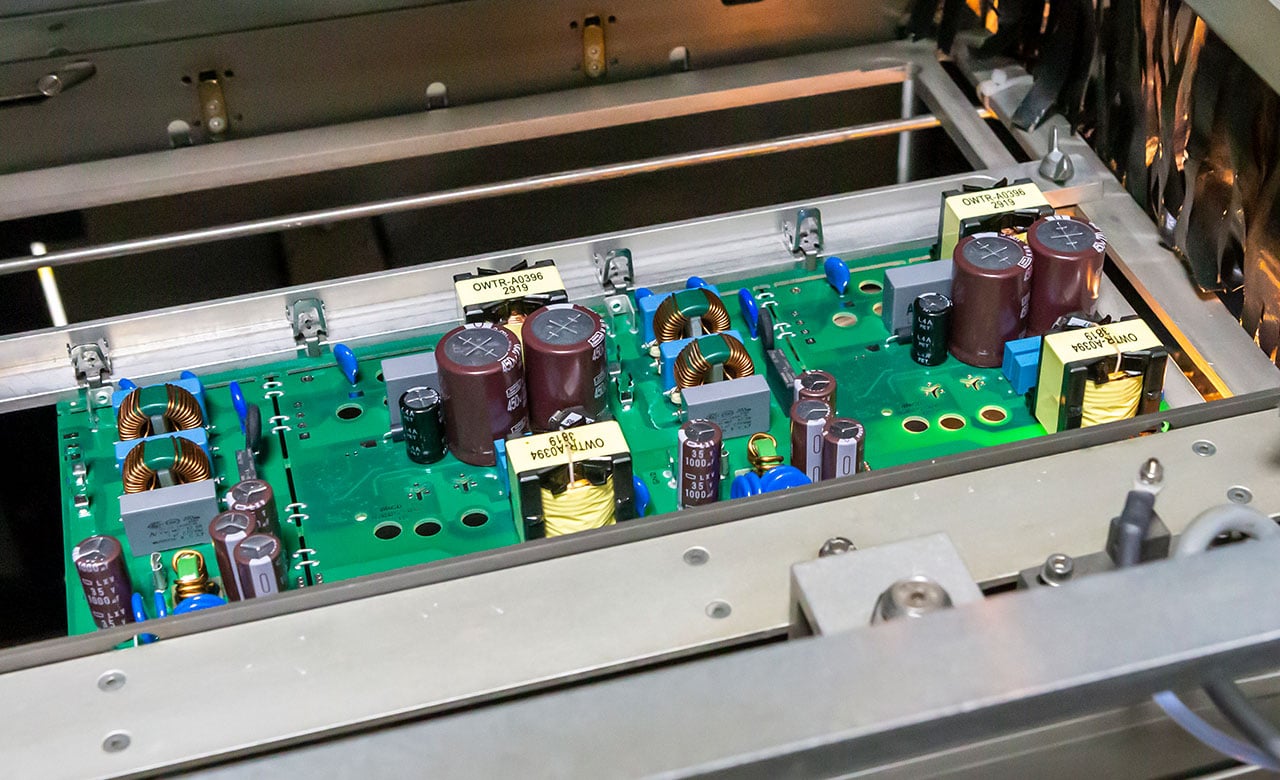

Connecting components to the circuit board

Soldering on the PCB solder side

The soldering process takes place from below, with a wave soldering system pulling the entire assembly over a wave of liquid solder. The solder wave wets the inserted pins with solder and makes contact with the conductor tracks.

If the THT assembly requires greater accuracy, for example with double-sided assembly, ACD Systemtechnik uses the selective soldering system or manual soldering. Our capabilities as an EMS assembler range from single pieces to large quantities and we therefore use the existing soldering processes as intended: Large numbers of mixed-assembly (SMD one-sided) and hand-assembled circuit boards are soldered in a highly automated manner using the state-of-the-art wave soldering system.

Automatic soldering with through hole technology

PCB solder side SMD assembly

If the circuit boards are equipped with SMDs on both sides and also have wired components, then the soldering process selective soldering is used. To do this, a soldering program is written so that the soldering nozzles target individual points on the PCB soldering side.

Due to the possibility of using nozzles of different diameters, the exact amount of solder required can always be applied to the individual soldering points in order to guarantee a safe and long-term stable electrical connection.

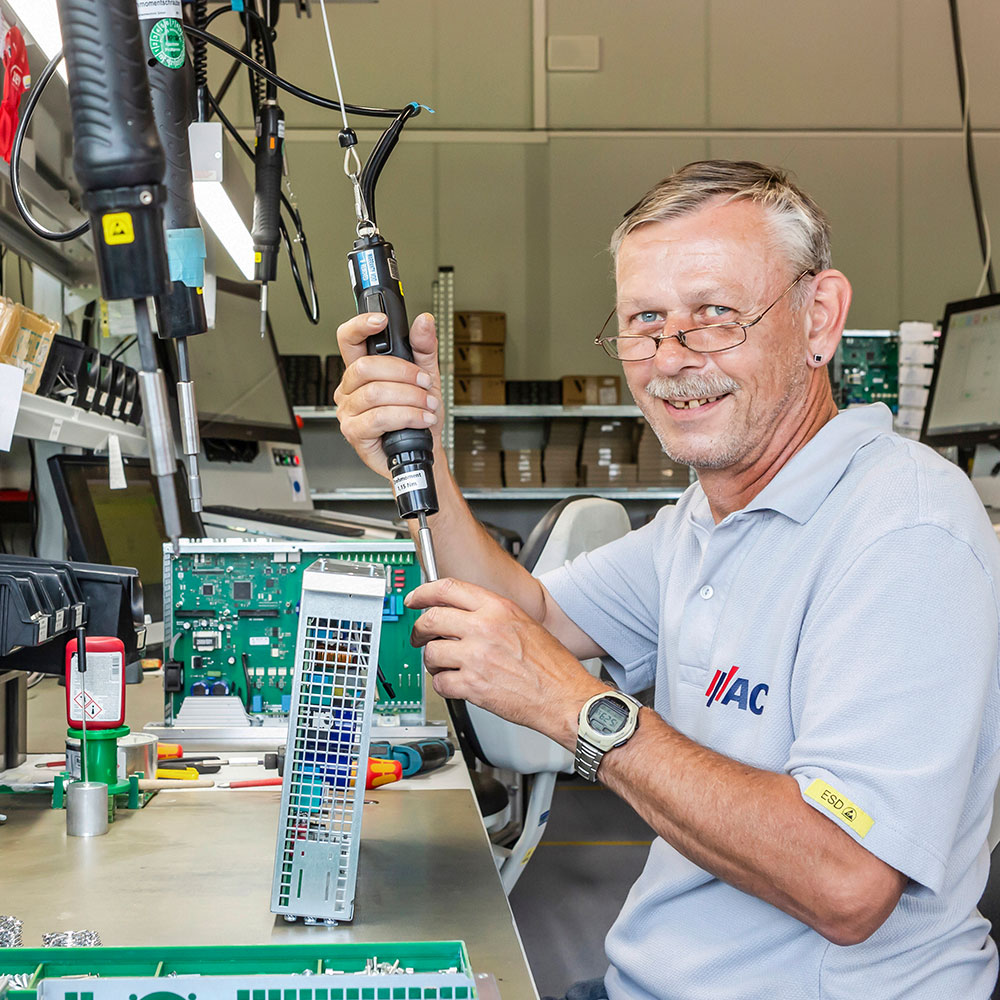

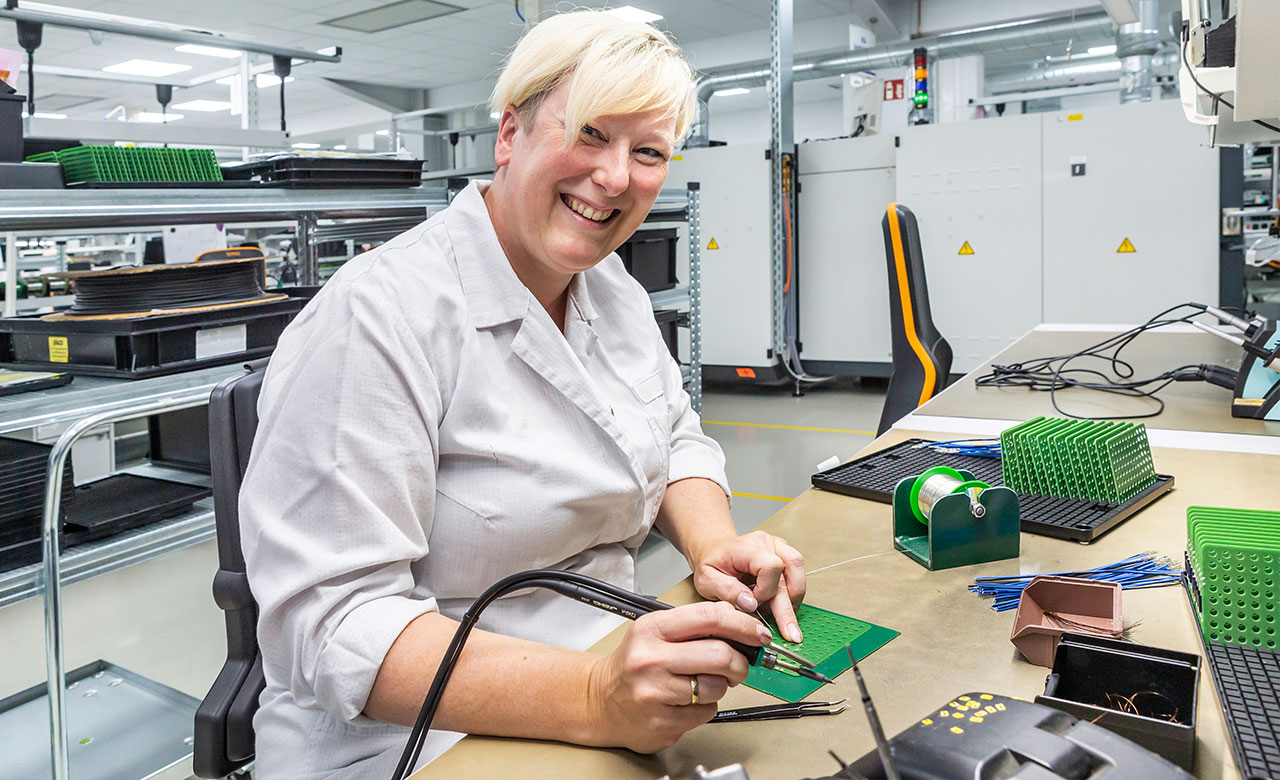

Soldering through-wired components manually

Professional hand soldering

For small quantities, trained specialists solder the assembled components by hand at special manual workstations. Here, non-machine-solderable connectors with press-fit technology and oversized components are also processed. Mechanical brackets and fastenings round off the work profile for THT hand soldering.