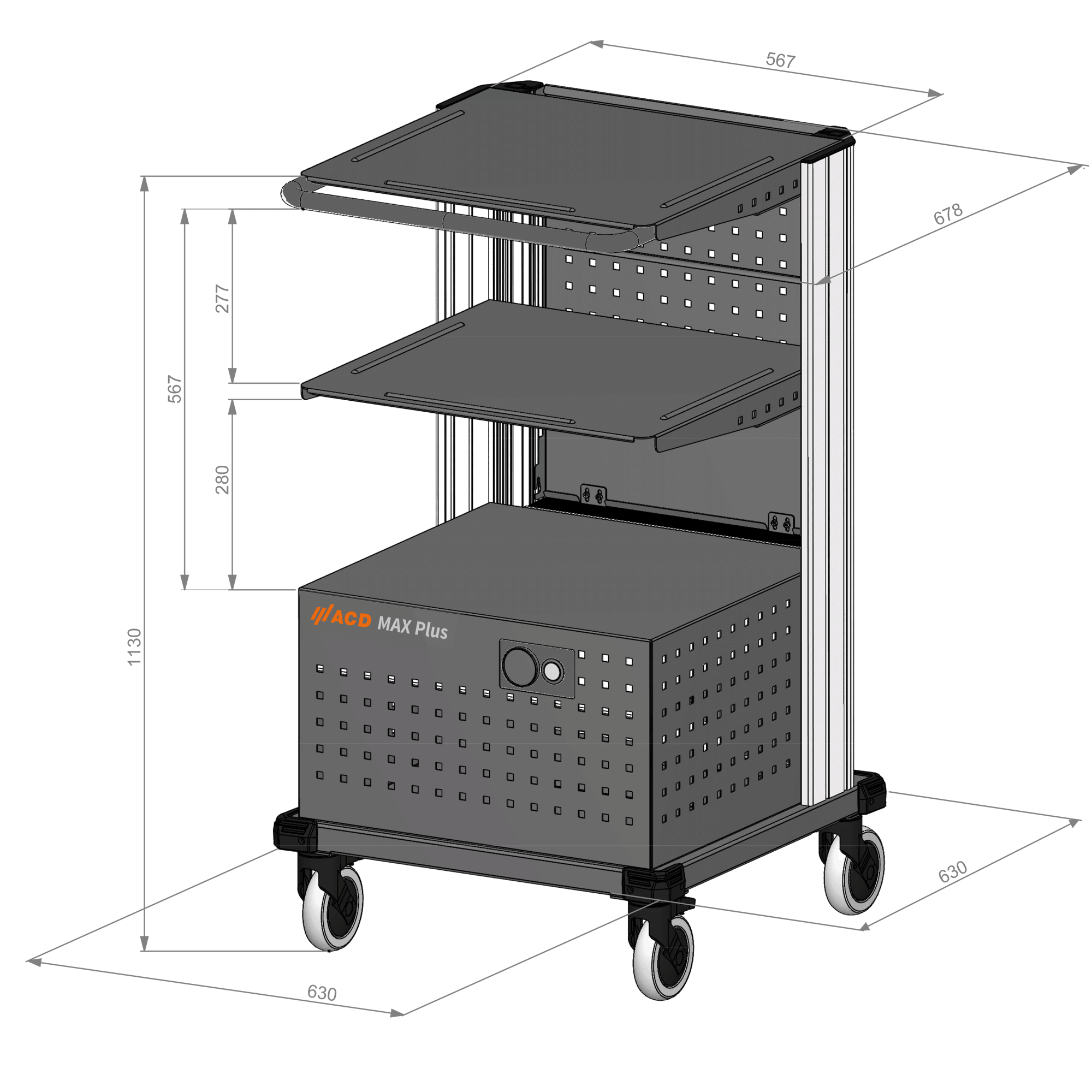

Mobile Workstation MAX BE

MAX BE Mobile Workstation: Mobilize warehouse IT and reduce work pathway

The MAX BE Mobile Workstation is ideally suited to flexible data collection and independent work in the warehouse environment including logistics, goods in / cross docking, shipping and inventory control.

Product Information

Mobile Workstation MAX BE

Adapted to your needs, an independent Mobile Workstation can be used, for example, to record incoming goods in the IT system directly in the delivery area. The MAX BE mobile cart means, among other things, a considerable shortening of distances, accelerated storage and the saving of fixed PC workstations. The extremely robust design and the flexible modular system ensure a workstation that is tailored to requirements and optimized for the process.

The Mobile Workstation MAX BE offers a clear and demonstrable efficiency advantage. Use the ROI calculator to calculate your savings potential through the use of Mobile Workstations in the warehouse.

Mobile Workstation MAX BE: Saves travel time and makes it equipment mobile

- Industrial design, configurable as you wish

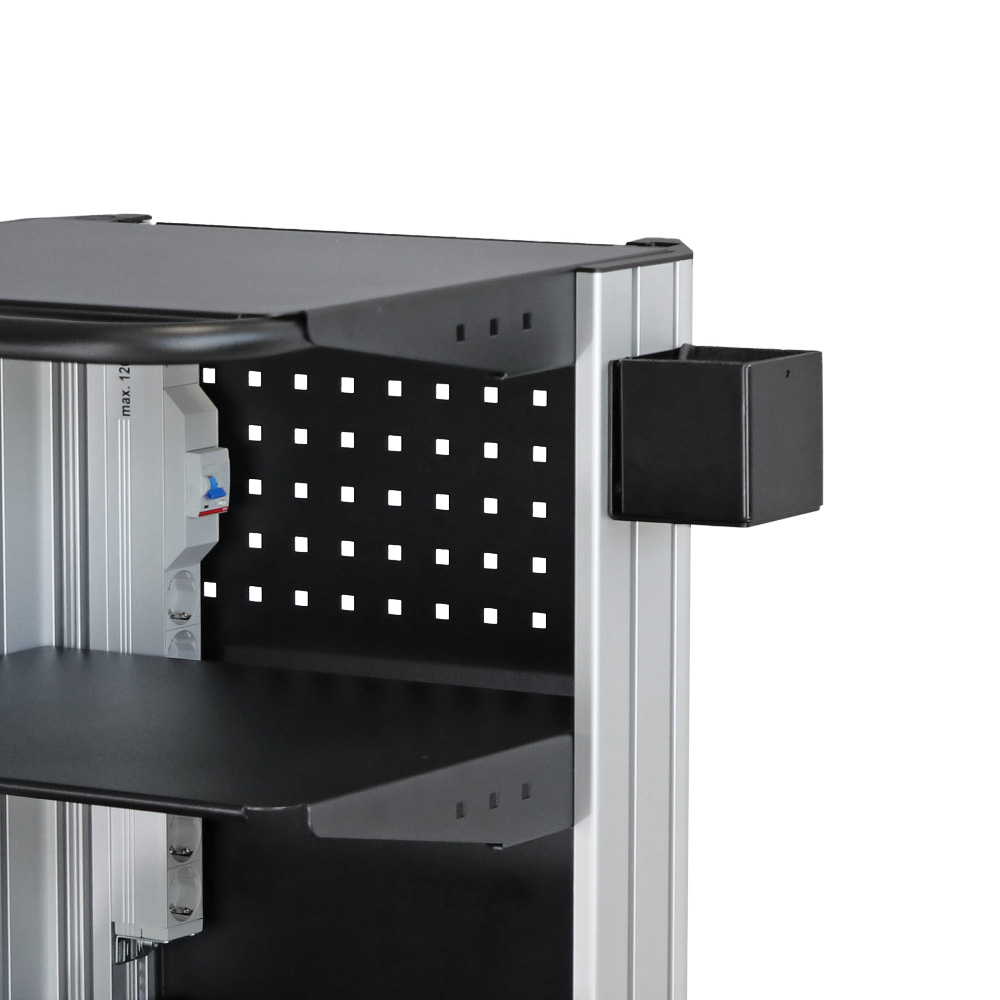

- Base frame with perforated grid for flexible attachment of accessories

- Can be used around the clock: battery exchange system, fast charging, intermediate charging

- Tailored for laser printer

- Safe with FI circuit breaker, tested and approved

- Fast amortization (ROI calculator)

A short video about the use of our Mobile Workstation at Goldhofer AG in Memmingen shows very clearly how travel time can be saved and IT equipment can be made mobile.

Special and customized solutions:

Upon request, ACD designs and manufactures Mobile Workstations and picking carts based on and know-how of our standard components according to your individual specifications. Enclosed some examples:

- PC trolley

- Service trolley

- Mobile test station

- Care trolley

- Remote maintenance system

- Mobile desk

- Special mounts

Technical variants

MAX BE versions

MAX BE BWS-R

The MAX BE BWS-R features a roller battery changing system for easy battery changing without lifting.

Product Equipment

Accessories

Extension support for keyboard and mouse.

Rear panel.

Hinged rear panel with document bag.

Table top with grip.

Table top with grip, 700 x 600 mm, variable height.

Table top 1100 x 680 mm.

Table top B500 middle – without grip.

Fully extendable table top without grip.

Easy way to adjust the height of the table top B500 top – with handle via an adapter plate and two eccentric quick clamps.

Plate for table top with 500 mm depth.

Printer Shelve rear panel. Carrying capacity 25 kg, please note weight compensation.

Printer Shelve rear panel. Carrying capacity 22 kg, please note weight compensation.

Drawer module with lock. Dimension: 500 x 160 x 440 mm (W x H x D).

Drawer module with divider insert for small items without lock. Dimension: 500 x 80 x 440 mm (W x H x D).

Magnetic holder for storing.

Holder for side mounting and storage.

Holder for side mounting and storage.

Holder for side mounting and storage.

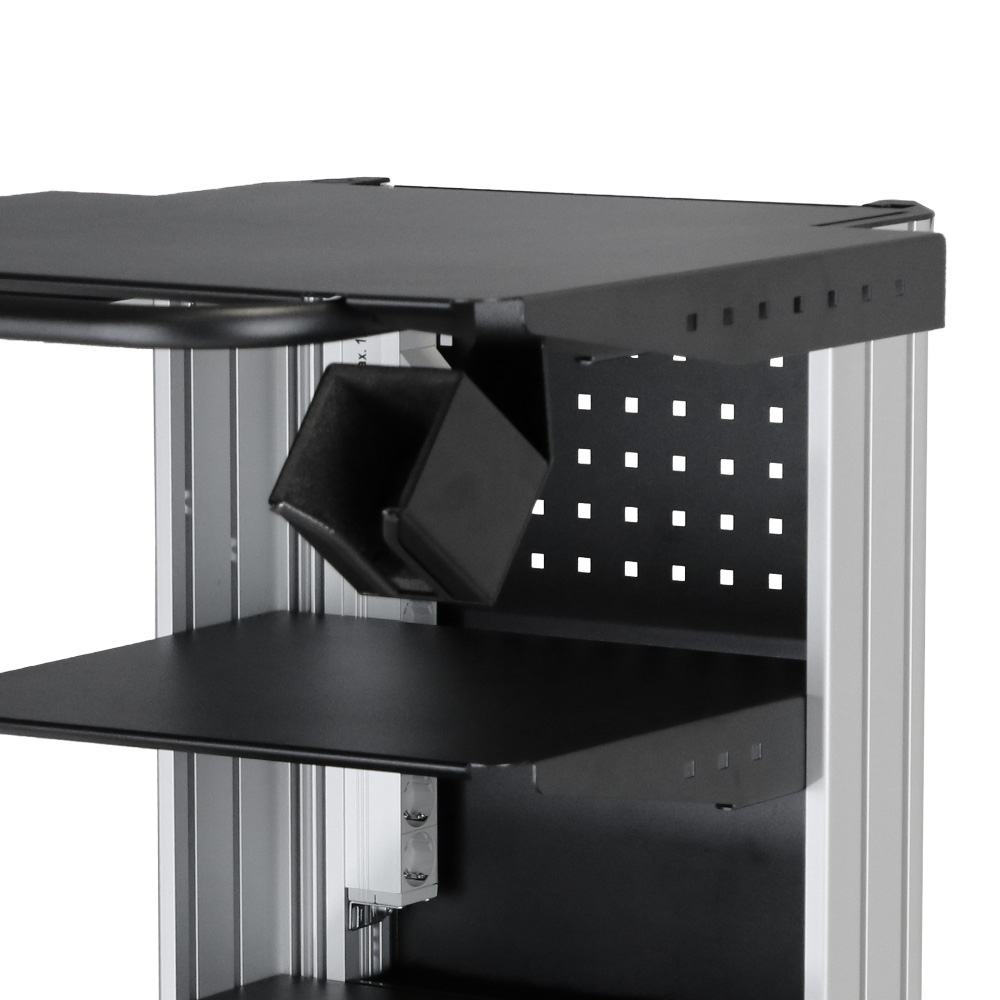

Inclined scanner holder for attachment to large B700 table top with foam and 45° mounting bracket.

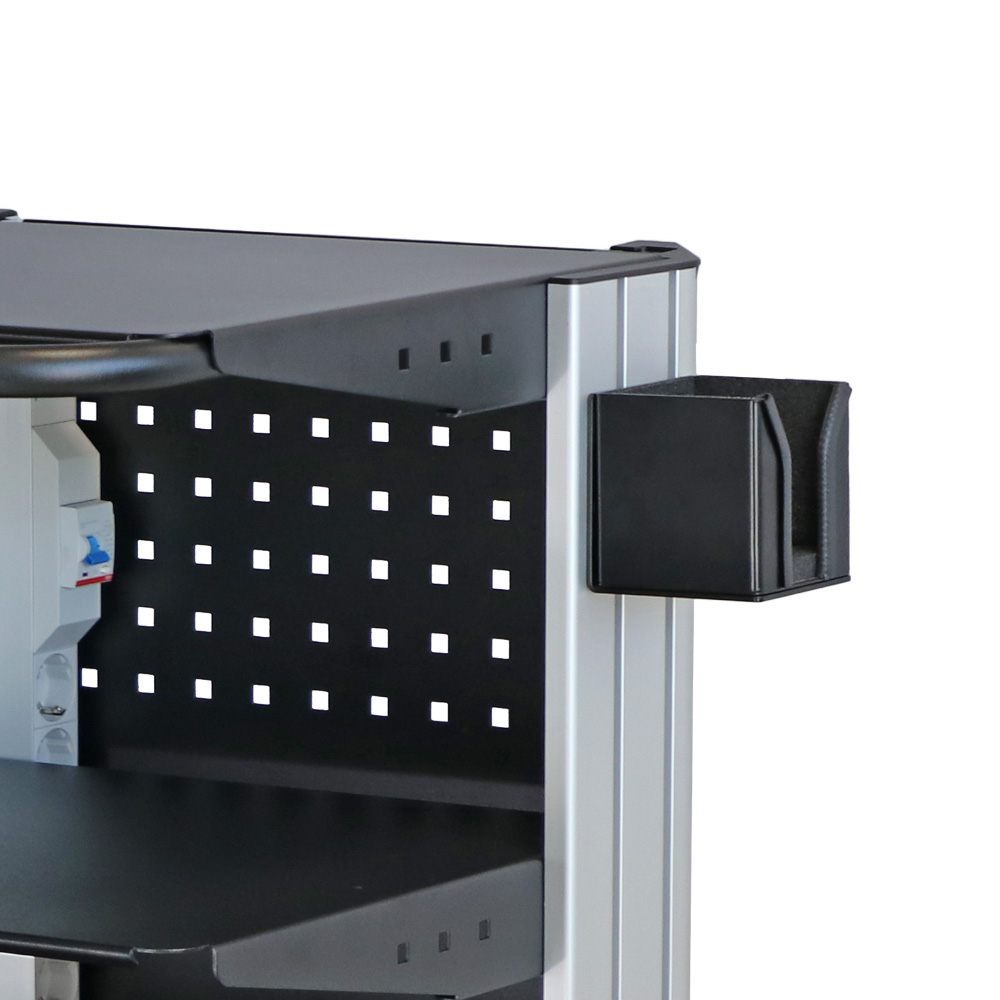

The lateral storage box consists of a sturdy plastic box and a mounting bracket. The storage box is attached to the side of the frame of the mobile workstation.

MAX holster bag incl. mounting kit for the M2Smart®SE or the M2Smart®SE with M2Key16 logistics module (with and without handle), which can be attached to the mobile workstation via an angle on the extruded profile.

Special version – customised to label.

Special version – customised to label.

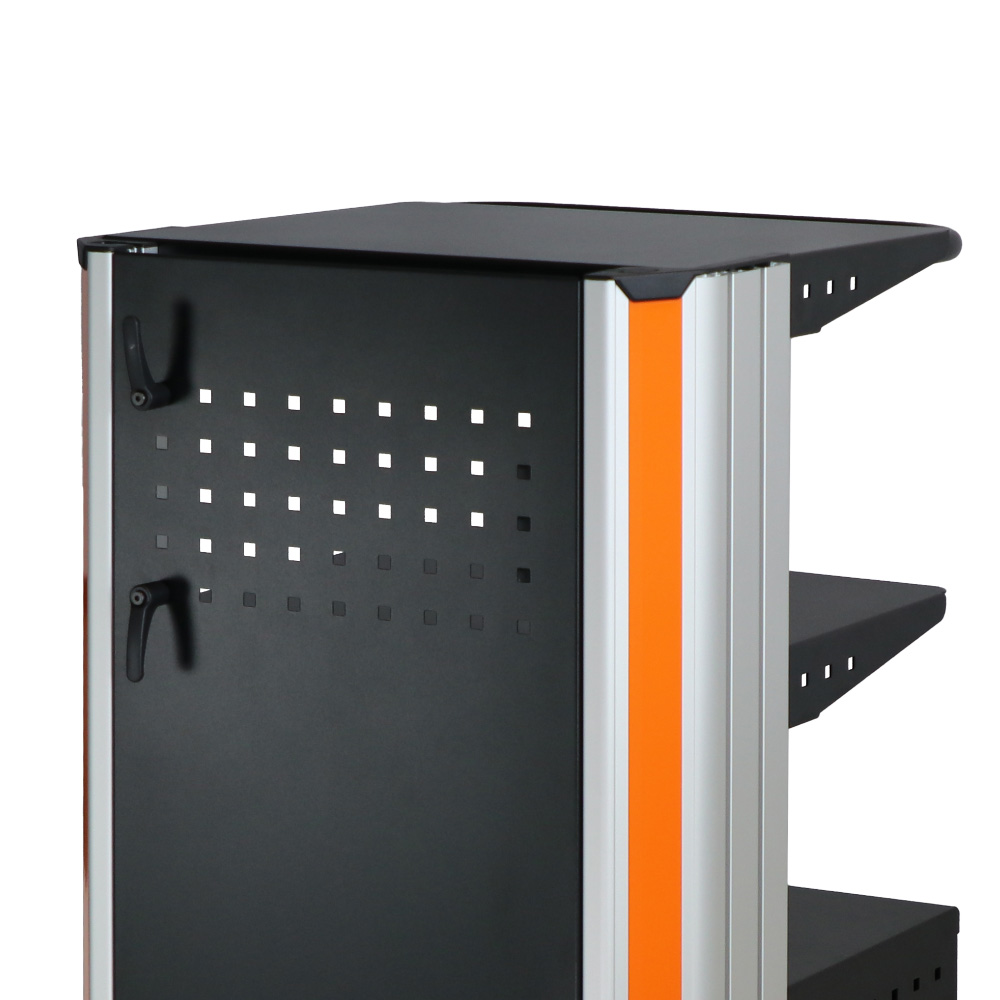

Shelf can be folded in/out at the side, dimension: 420 x 345 mm (W x D), max. load 5 kg.

Fine grooved rubber mat 3 mm for table top B500.

Fine grooved rubber mat 3 mm for swivel plate B420.

Fine grooved rubber mat 3 mm for table top B700 top with handle extra large.

Aluminium monitor holder with two joints. Suitable for LCD/TFT monitors with max. 7 kg.

Steel monitor holder with one joint and clamp lock for height adjustment. Suitable for LCD/TFT monitors with max. 15 kg.

Additional holder with a joint and clamp lock for height adjustment for VESA 75/100 monitor support (pillar). Used to attach a second monitor or a thin client mount. Suitable for monitors with max. 10 kg.

Steel monitor holder with one joint and clamp lock for height adjustment for vertical mounting of two monitors. Suitable for LCD/TFT monitors with a maximum weight of 15 kg each.

Steel monitor holder with one joint and clamp lock for height adjustment for holding two monitors horizontally. Suitable for LCD/TFT monitors with a maximum weight of 15 kg each.

Aluminium monitor holder with two joints. Suitable for LCD/TFT monitors with max. 6 kg (arm vertical).

Aluminium monitor holder with two joints. Suitable for LCD/TFT monitors with max. 6 kg (arm vertical).

Aluminium monitor holder with two joints. Suitable for LCD/TFT monitors with max. 6 kg (arm vertical).

Bracket in black for internal, side mounting of thin client PCs. Attachment to the frame or via VESA 50/75/100 mm. Width adjustable: max. 100 mm, maximum load: 10 kg.

Waste box/ dustbin; 40 litres.

Magnetically attachable waste box/ dustbin; 10 litres.

Mounting set for ramming protection of the mobile workstation on three sides (rear, left, right).

Cable holder without cable, mounted on the back.

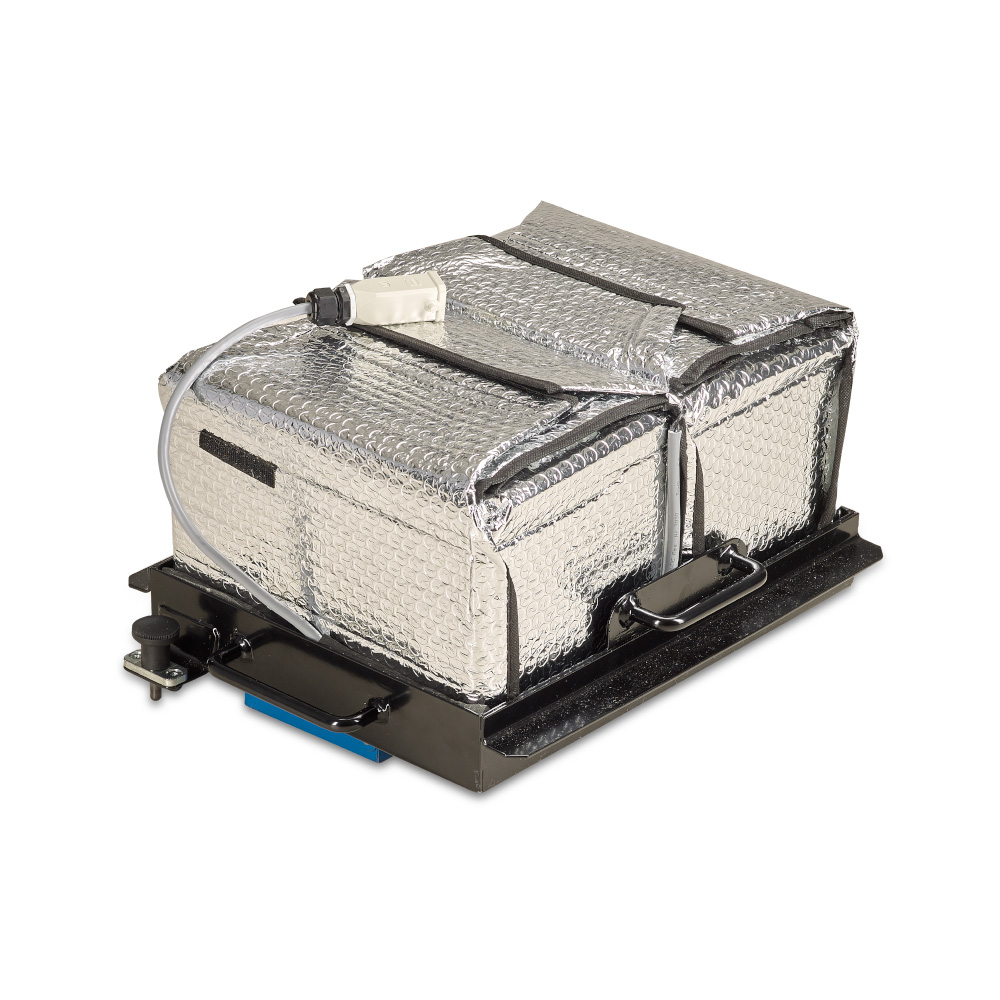

Protection cover small, 1200 x 600 x 600 mm (H x W x D) for Mobile Workstation with Table top B500.

Protection cover medium, 1200 x 800 x 800 mm (H x W x D) for Mobile Workstation with Table top B700.

Protection cover large, 1110 x 1350 x 800 mm (H x W x D) for Mobile Workstation with Table top B1100.

Velcro cable fastening set with 5x fastening bases (self-adhesive), 5x Velcro strips and 10x cable ties.

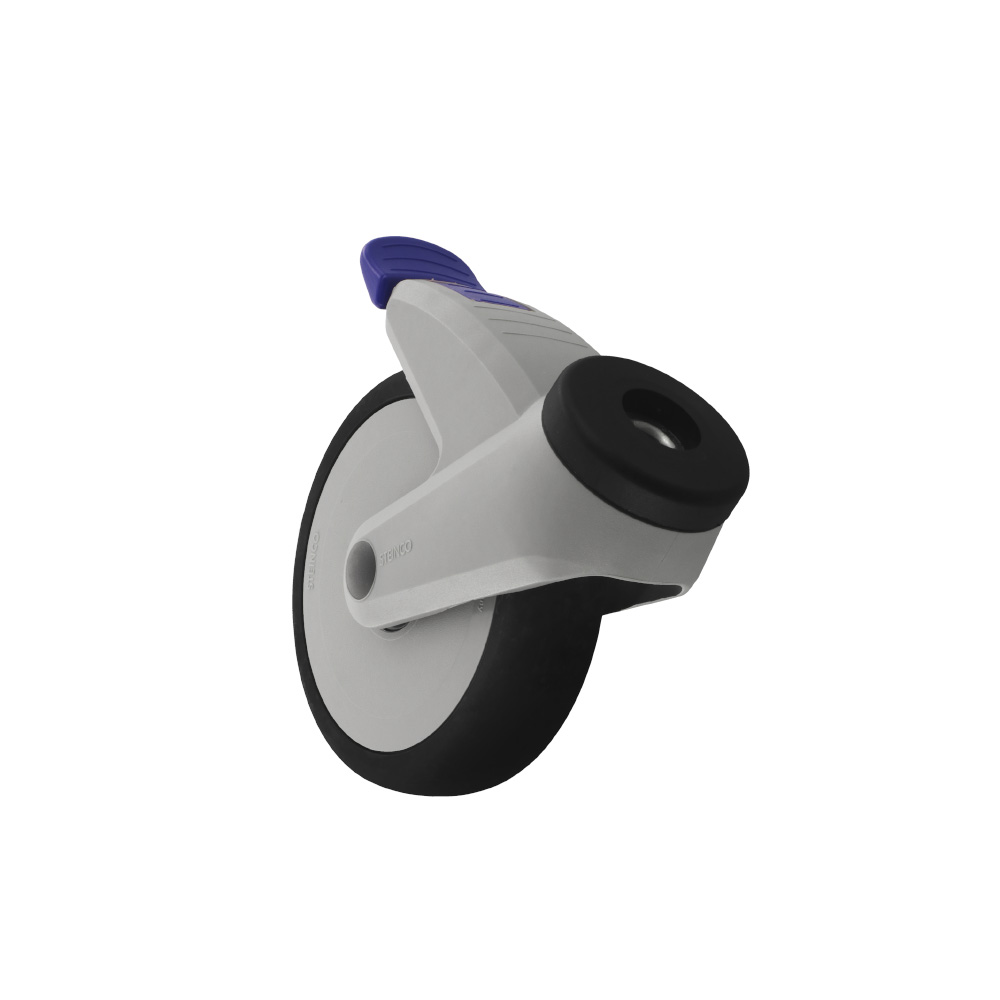

Lockable caster with parking brake.

Diameter 150 mm with air-identical tyre (air-foamed). Smooth running on uneven surfaces (e.g. tarmac).

Conversion kit for replacing the rear swivel castors with fixed castors.

Bluetooth module, integrated in the battery management system of the MAX BE Li-Ion to display the charge status via the Bluetooth Smart Dongle app.

USB connection of the MAX BE Li-Ion to a Windows® computer.

Version for Germany incl. residual current device (RCD).

Version for Switzerland incl. residual current device (RCD).

Version for Great Britain incl. residual current device (RCD).

Version for France/Belgium incl. residual current device (RCD).

Battery change tray for MAX BE BWS-R with and without inverter.

Battery change tray for MAX BE BWS-R as freezer use version.

Chargers for MAX BE. Assembled with 2-pin charging plug.

Chargers for MAX BE TK. Assembled with 4-pin charging plug.

Case Study

A Successor for Worn-out Roll Carts Had to Be Found

A high-performance logistics concept is an indispensable prereq uisite for the corporate group to be able to send off goods deliveries punctually. To ensure this, EDEKA had for some years already been using mobile workstations with lead batteries to receive products arriving in incoming goods.

Case Study

State of the Art in the New Goldhofer Logistics Center

Andreas Schneider, Warehouse Manager at Goldhofer, is enthusiastic about the solution: “lt meets our needs exactly. The portable workstation provides excellent mobility. lt also has rollers that move very easily. The MAX is a lean vehicle that was customized specifically for us with numerous options, modifications and accessories.”

Similar Products

Products that might also interest you

PowerBox PB300 BE Li-Ion

Mobile power supply

The PowerBox is particularly suitable as a secure, mobile power supply throughout the logistics environment.

Configurator

Mobile Workstation MAX BE

Independent work in the warehouse environment

The Mobile Workplace makes IT equipment mobile and saves travel time.

Configurator

Downloads

Current flyers and catalogues

Downloads

Technical documentation

Mobile Workstation MAX

Your companion in the incoming goods department

Each warehouse has different requirements depending on the personnel used, the processes performed and the materials stored. With this in mind, we have designed and developed various mobile workstations that are designed to meet a wider range of system requirements and constraints.

Configure your mobile workstation!

In the Mobile Workstation MAX product configurator the suitable Mobile Workstation can be configured quickly and easily according to individual requirements. All MAX models are characterized by a flexible modular system, which allows users to adapt the system to their requirements. The country-specific design also meets all EU and CSA/US requirements. A proven battery management system ensures a longer battery life and industrial grade castors facilitate movement in the warehouse.

Advantages of the Mobile Workstation MAX in logistics and other industries

Mobile workstations – like those of the MAX series – offer a number of advantages that increase profitability:

- Increased productivity: Mobile workstations allow employees to take their workstations to different locations in the warehouse and thus reduce the travel time between the workstation and the warehouse stock.

- Improved data access: Since the workstation is immediately available, employees can easily access the information needed for accurate order processing and documentation of shipping and returns.

- Simplified docking and shipping procedures: Without the need to move between different areas of the warehouse to obtain products, materials and documentation, docking and shipping are also much easier. With the help of a mobile workstation, warehouse workers have all information in place, enabling streamlined shipping and receiving processes.

- Lower error potential: Since employees have a direct overview of all relevant data, the probability of information being overlooked, forgotten or misinterpreted is reduced – thus reducing the error potential for shipping, returns and inventory controls.